Home

Machinery part

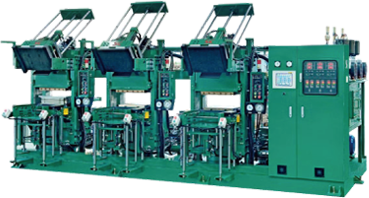

RUBBER COMPRESSION MOLDING M/C

RUBBER COMPRESSION MOLDING M/C

- As the internal chamber is pressured in vacuum condition, bubbles and malforming loss are prevented and suitable for high precision products.

- Minimized the over hole and can be reduced the loss of materials.

- Be capable of reducing setting times of operating conditions of same items by storaging operating conditions (20set) by touch screen monitor and prompt remedy to the breakdowns and operation is possible by preserving messages(195items) for the operations and defects.

- Efficient production management is possible by computer communication because of the receiving data at the computer room with real time (option)

SPECIFICATION

| Item | SC- V1540 |

SC- V2040 |

SC- V2550 |

SC- V3560 |

SC- V4070 |

SC- V5080 |

SC- V6090 |

SC- V80100 |

SC- V110120 |

SC- V150150 |

SC- V200200 |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Clamping force | ton | 110 | 200 | 250 | 350 | 400 | 500 | 600 | 800 | 1,000 | 1,500 | 2,000 |

| Heating plate size | mm | 300× 360 |

400× 460 |

500× 560 |

600× 600 |

700× 700 |

800× 800 |

900× 900 |

1,000× 1,000 |

1,200× 1,200 |

1,500× 1,500 |

2,000× 2,000 |

| Daylight | mm | 260 | 300 | 320 | 350 | 350 | 550 | 550 | 650 | 650 | 750 | 750 |

| Mold thickness | mm | 0~180 | 0~180 | 0~180 | 20~270 | 20~270 | 110~390 | 110~390 | 110~490 | 110~490 | 110~590 | 110~590 |

| Max.pressure | kgf/㎠ | |||||||||||

| Operating pressure | kgf/㎠ | 200 | 190 | 190 | 190 | 190 | 190 | 190 | 190 | 190 | 190 | 190 |

| Low-pressured pump cap | ℓ/min | 26 | 26 | 26 | 26 | 26 | 40 | 40 | 60 | 60 | 100 | 100 |

| High-pressured pump cap | ℓ/min | 12 | 17 | 19 | 23 | 25 | 32 | 32 | 40 | 40 | 60 | 60 |

| Motor capacity< | HP×P | 10×6 | 10×6 | 10×6 | 15×6 | 20×6 | 25×6 | 25×6 | 30×6 | 30×6 | 40×6 | 40×6 |

| Heater capacity | kw | 6.6 | 6.6 | 7.8 | 13.8 | 19 | 25 | 32 | 40 | 48 | 56 | 64 |

| Press-uni | unit | 3×1, 4×1 |

2×1, 3×1 |

2×1, 3×1 |

2×1, 3×1 |

1×1, 2×1 |

1×1, 2×1 |

1×1, 2×1 |

1×1 | 1×1 | 1×1 | 1×1 |

※ Can be changeable without any notice.

* Move left and right